Automated Crane

For the TCH098 end-of-term engineering project, our team of five was tasked with designing and building an automated crane from concept to production, assembly, and programming. Each team member contributed expertise from different engineering disciplines to complete the project.

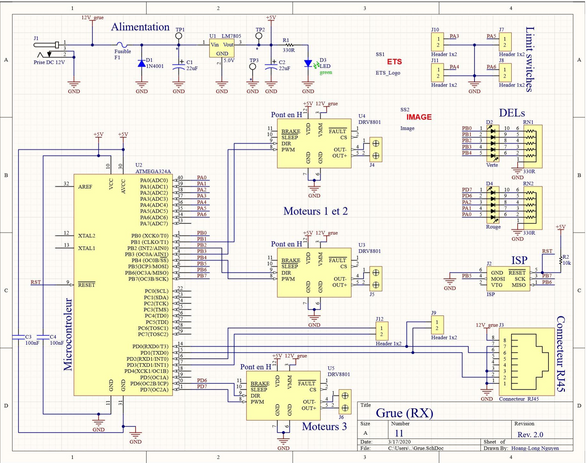

My first major responsibility was designing the controller and receiver systems that would allow for both manual and automated crane operation. We began by prototyping the circuits on a breadboard, testing different configurations before finalizing the design. Once validated, we transferred the circuit to Altium Designer, where I designed and routed the PCBs for both the controller and receiver, ensuring reliable communication and functionality.

The second phase of my work focused on programming the crane’s microcontroller, which served as the system's brain. Using AVR Studio, I programmed an 8-bit ATmega microcontroller in C, first implementing basic manual crane movements. Once the manual controls were functional, I developed an automated routine, requiring the crane to follow a predefined path set by the instructors. This involved picking up a weight from one location and moving it to another without manual input, ensuring precise movement sequencing and error handling.

Beyond the technical challenges, this project gave me valuable experience in engineering teamwork, problem-solving, and leadership. Coordinating with my teammates to integrate mechanical, electrical, and software components gave me insight into real-world engineering workflows. It also reinforced my ability to lead tasks, manage timelines, and troubleshoot complex system interactions, making it a highly educational and rewarding experience.